Categories

New Products

Single head self-priming bag filling and capping machine with 60L gear pump Welcome to visit our factory! more

Food Grade Full Automatic Single Head Powder Can Filling & Capping & Laser Coding Machine Line This production line is suitable for canning and packaging of corn flour, lotus root flour, chicken essence powder and other powder materials. more

High Quality Full Automatic Food Can Sauce Filling&Sealing Packing Line This production line is suitable for viscous materials such as tomato sauce, salad sauce, chili sauce, etc. more

Full Automatic Vertical Volumetric Cup Filler Type Granule Sachet Packing Machine Apply for regular granular packing, such as sugar, soybean, rice, corn, sea salt, edible salt and plastic products, etc. more

High Quality Full Automatic Multi-Lane Back Sealing Granule Sachet Packing Machine Suit to granule: salt, sugar, coffee, wash powder, seasoning, etc. more

High Quality Full Automatic Multi-Lane Liquid & Cream Sachet Back Sealing Packing Machine Suit to liquid: sport gel, sauce, honey, medicinal liquid, cream, jelly, etc. more

High Quality Full Automatic Multi-Lane Sachet Back Sealing Powder Packing Machine Suit to Powder: milk powder, flour, seasoning powder, medicine powder, protein powder, etc. more

Hot sell shampoo lotion soap heating mixer machine This Heating Mixer Machine is suitable for cosmetics, chemical, pharmaceutical, food and other industries. Easy to operate and easy to use. more

All-in-one Automatic Liquid Filling Weighing And Cartoning Machine The Automatic Liquid Filling Sealing Machine is suitable for liquid, medicine, beverage, electronic cigarette oil, dairy product, health product, food, perfume, pesticide,cosmetics, fruit pulp, oil, etc. more

High Speed Oral Automatic Liquid Filling Sealing Machine APPLISCATION The Oral Liquid Filling Sealing Machine is suitable for unit metering of medicine, dairy product, health product,food, beverage, cosmetics, perfume, pesticide, fruit pulp etc. more

Full automatic pharmaceutical liquid filling and sealing machine This Oral Liquid Filling Machine is suitable for liquid, health products, food, perfume, medicine, beverage, pesticide, cosmetics, e-cigarette oil, dairy products, fruit pulp, oil and so on. more

Automatic Pharmaceutical Oral Liquid Filling and Sealing Machine The Liquid Filling and Sealing Machine is suitable for liquid, medicine, beverage, health product, food, perfume, pesticide,cosmetics, electronic cigarette oil, dairy product, fruit pulp, oil, etc. more

This Automatic Sealing Machine adopts PLC intelligent programming and touch screen control, which is convenient and simple to use and set, applicable to food, pharmaceutical, cosmetic, chemical and other industries.

Item NO.:

MZH-TSPayment:

T/T D/P D/A L/C MoneyGramProduct Origin:

Guangzhou ChinaColor:

Stainless steel 304/316Shipping Port:

HuangpuLead Time:

35 working daysAutomatic rotory tin can sealing machine

Customized And OEM Service Available

I. Equipment performance description and characteristics

1. This Rotory Sealing Machine Sealing diameter φ 40 ~ φ 130mm, sealing height 60 ~ 220mm;

2. Adjustable production efficiency, up to 50 cans per minute;

3. The overall appearance is mainly made of stainless steel 304 with a thickness of 1.5mm;

4. PMMA is made of imported acrylic with a thickness of 10 mm;

5.The hob adopts 4 hobs for sealing, the sealing force is more uniform, and the sealing performance index is excellent;

6. It has the function of alarm prompt and cover in case of missing cover, so as to ensure the

efficient and uninterrupted operation of the equipment;

7. Set up uncapped and unsealed tank and failure detection shutdown, effectively reduce equipment

failure;

8. The lower capper can cover 200 pieces (one cylinder) at a time;

9.The mold needs to be replaced when changing the caliber, and the replacement time is about 40

minutes;

10.The diameter needs to be changed; the pressure head + lower cover device + turntable +

guardrail, the cans and covers of different materials need to be changed to the sealing roller;

11. Change the height of can sealing without changing accessories, adopt the design of hand screw

rod, adjust the time about 5 minutes;

12. Before delivery and use, the sealing effect shall be tested by strict testing means to ensure the

product quality;

13. The defect rate is very low, less than 1 / 10000 for iron cans, less than 1 / 1000 for plastic cans

and less than 2 / 1000 for paper cans;

14. The head is quenched with chromium 12 molybdenum vanadium, with hardness over 50

degrees and service life over 1 million tanks;

15. This Tin Sealing Machine roller is imported from Taiwan, and the hob material is SKD Japanese special die steel, with

a service life of more than 5 million times of sealing;

16. The conveyor belt is 3M long, 0.9m high and 114mm wide;

17. The size of the equipment is 2.95 * 0.95 m * 1.7 m in length * 0.95 m * 1.7 m in height, and the

size after packing is 1.60 m × 1.20 m × 2.04 m;

18. The net weight is about 500kg and the gross weight is about 550Kg;

19. Main motor power: 1.1kw/220v, conveyor belt motor: 0.2kw/220v, total power: 1.3KW

20. The conveyor belt is made of nylon POM and the chuck is made of PP board;

21. The air compressor needs to be configured additionally. The power of the air compressor is

more than 3KW, and the air supply pressure is 0.6kpa;

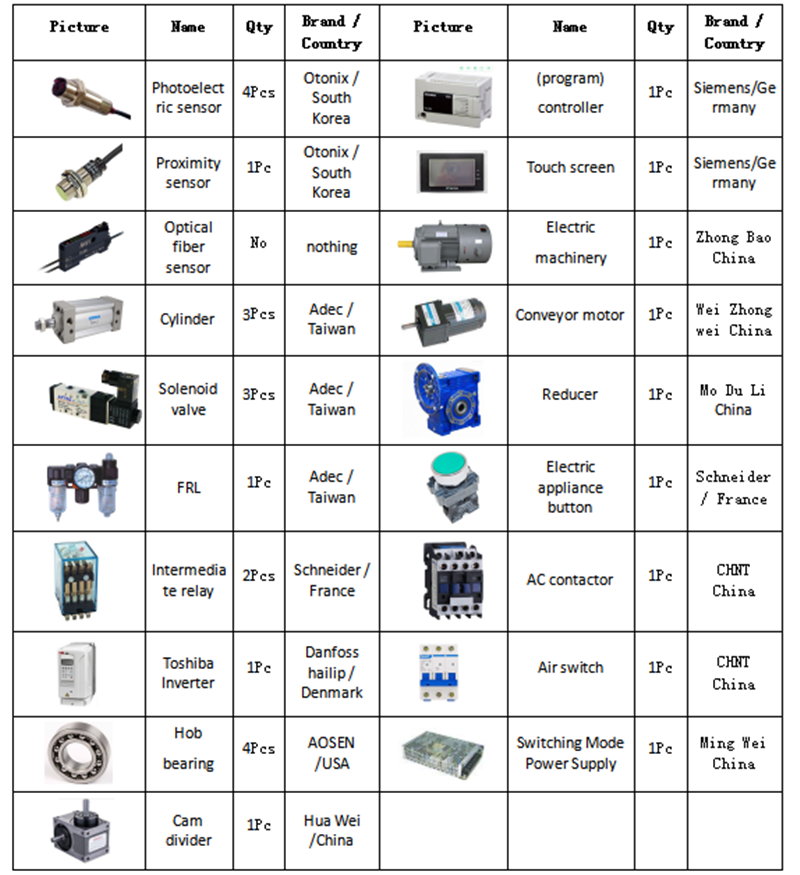

II. Electrical configuration list of equipment is as follows

III. list of random tools

1.One set of standard 6-point key; 2. One hook wrench; 3. One open-end wrench for 17 and 19; 4. One manual; 5. One photoelectric screwdriver

IV. optional spare parts

1.Photoelectric switch and proximity switch; 2. Indenter; 3. Hob; 4. Air cylinder; 5. Motor

V. warranty period

Within one year after the delivery of the equipment, the quality problems shall be free of charge for on-site maintenance (only in mainland China), and the warranty period of spare parts is as follows:

Core parts (CAM, gear, main shaft, shaft sleeve, bearing and synchronous pulley) two years free

VI. warranty;

One year free warranty for motor and index plate;

One year free warranty for programming processor, solenoid valve, relay, cylinder, photoelectric switch, proximity switch, AC contactor, touch screen and pneumatic triple parts;

One year free warranty for belt and synchronous belt

Prev:

Totary drum automatic bottle sealing machineNext:

Automatic inductor plastic bottle aluminum foil sealing machineIf you have questions or suggestions,please leave us a message,we will reply you as soon as we can!