Categories

New Products

Single head self-priming bag filling and capping machine with 60L gear pump Welcome to visit our factory! more

Food Grade Full Automatic Single Head Powder Can Filling & Capping & Laser Coding Machine Line This production line is suitable for canning and packaging of corn flour, lotus root flour, chicken essence powder and other powder materials. more

High Quality Full Automatic Food Can Sauce Filling&Sealing Packing Line This production line is suitable for viscous materials such as tomato sauce, salad sauce, chili sauce, etc. more

Full Automatic Vertical Volumetric Cup Filler Type Granule Sachet Packing Machine Apply for regular granular packing, such as sugar, soybean, rice, corn, sea salt, edible salt and plastic products, etc. more

High Quality Full Automatic Multi-Lane Back Sealing Granule Sachet Packing Machine Suit to granule: salt, sugar, coffee, wash powder, seasoning, etc. more

High Quality Full Automatic Multi-Lane Liquid & Cream Sachet Back Sealing Packing Machine Suit to liquid: sport gel, sauce, honey, medicinal liquid, cream, jelly, etc. more

High Quality Full Automatic Multi-Lane Sachet Back Sealing Powder Packing Machine Suit to Powder: milk powder, flour, seasoning powder, medicine powder, protein powder, etc. more

Hot sell shampoo lotion soap heating mixer machine This Heating Mixer Machine is suitable for cosmetics, chemical, pharmaceutical, food and other industries. Easy to operate and easy to use. more

All-in-one Automatic Liquid Filling Weighing And Cartoning Machine The Automatic Liquid Filling Sealing Machine is suitable for liquid, medicine, beverage, electronic cigarette oil, dairy product, health product, food, perfume, pesticide,cosmetics, fruit pulp, oil, etc. more

High Speed Oral Automatic Liquid Filling Sealing Machine APPLISCATION The Oral Liquid Filling Sealing Machine is suitable for unit metering of medicine, dairy product, health product,food, beverage, cosmetics, perfume, pesticide, fruit pulp etc. more

Full automatic pharmaceutical liquid filling and sealing machine This Oral Liquid Filling Machine is suitable for liquid, health products, food, perfume, medicine, beverage, pesticide, cosmetics, e-cigarette oil, dairy products, fruit pulp, oil and so on. more

Automatic Pharmaceutical Oral Liquid Filling and Sealing Machine The Liquid Filling and Sealing Machine is suitable for liquid, medicine, beverage, health product, food, perfume, pesticide,cosmetics, electronic cigarette oil, dairy product, fruit pulp, oil, etc. more

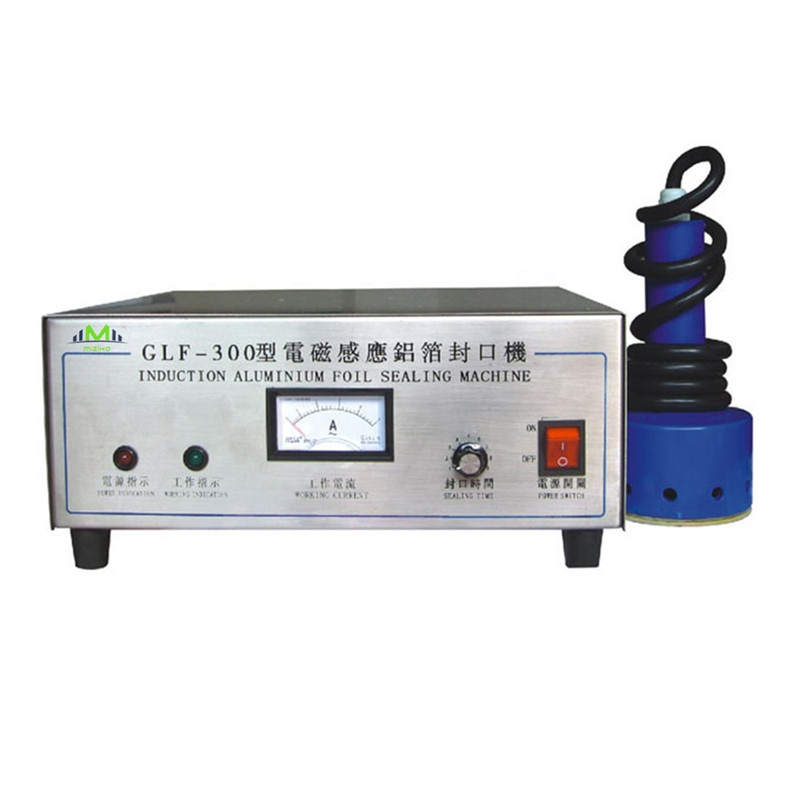

The Induction aluminum foil sealing machine, is used in medicine, chemical industry, beverage ,cosmetic etc, plastic glass packing container , Bottle Induction Sealing Machine is use aluminum foil sealing working .

Item NO.:

MZH-SPayment:

L/C,D/A,D/P,T/T,Western Union,MoneyGram paymeProduct Origin:

ChinaShipping Port:

Huangpu, GuangzhouLead Time:

25 working daysManual cap induction aluminum foil cap heat sealing machine for bottles

Customized And OEM Service Available

Product Description

Manual Aluminum Foil induction is also called Heat Induction Sealing Machine,

The machine is used in medicine, chemical industry, beverage ,cosmetic etc, plastic

glass packing container , aluminum foil sealing working. Its sealing dia 30-120mm.

Working Principle:

Bottle Induction Sealing Machine system using electromagnetic induction heating principle, a magnetic field is the use of high-frequency electric current through the inductor (also called Electromagnetic Induction Sealing Machine), when the magnetic field lines through the aluminum foil sealing material, instantaneous produces a large number of small vortex, the aluminum foil to high fever, the melt, melt compound on the aluminum foil to paste on the seal of bearing sealing material, to reach the purpose of quickly sealing.

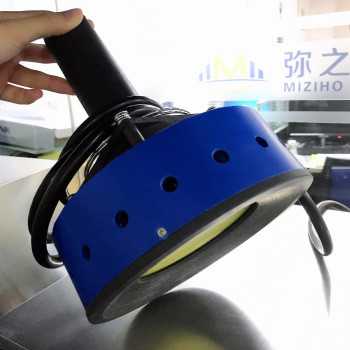

Detailed Images

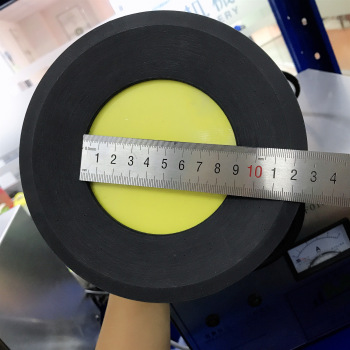

Sealing diameter:30-120mm (adjustable) can be continuously working

The control panel samples for reference

Certifications

FAQ

1. Q: Are you factory or trading company?

A: We are the professional manufacture of cosmetic machinery in China more than 15years,We have our own factory and skilled workers, rich-experienced R&D and professional service team.

2. Q: Where is your location?

A: Company and Showroom located in Guangzhou china, Factory located in Jiangsu and Shanghai Province.

3. Q:How about the Product Range?

A: We can provide a wide range of products for your One-stop sourcing. Also we can customize according to your specific requirements.

4. Q: How does your factory do regarding quality control?

A: Our quality is built on good quality material, imported from Japan, Germany etc. We have passed ISO9001,CE, GMP. Our price is based on the quality, and we will give reasonable prices to every customer.

5. Q:How about the after service?

A: We can give you one years after sales warranty, we can also send our engineer to you factory to install this equipment and train your staff, but the Buyer should pay the round air ticket cost and arrange the hotel accommodation as well as the means for Seller’s engineer. We will send some free set of spare parts for you change it.

Our Company to customer satisfaction for the development of three goals: product quality, product technology and after-sales service!

If you have questions or suggestions,please leave us a message,we will reply you as soon as we can!