Categories

New Products

Single head self-priming bag filling and capping machine with 60L gear pump Welcome to visit our factory! more

Food Grade Full Automatic Single Head Powder Can Filling & Capping & Laser Coding Machine Line This production line is suitable for canning and packaging of corn flour, lotus root flour, chicken essence powder and other powder materials. more

High Quality Full Automatic Food Can Sauce Filling&Sealing Packing Line This production line is suitable for viscous materials such as tomato sauce, salad sauce, chili sauce, etc. more

Full Automatic Vertical Volumetric Cup Filler Type Granule Sachet Packing Machine Apply for regular granular packing, such as sugar, soybean, rice, corn, sea salt, edible salt and plastic products, etc. more

High Quality Full Automatic Multi-Lane Back Sealing Granule Sachet Packing Machine Suit to granule: salt, sugar, coffee, wash powder, seasoning, etc. more

High Quality Full Automatic Multi-Lane Liquid & Cream Sachet Back Sealing Packing Machine Suit to liquid: sport gel, sauce, honey, medicinal liquid, cream, jelly, etc. more

High Quality Full Automatic Multi-Lane Sachet Back Sealing Powder Packing Machine Suit to Powder: milk powder, flour, seasoning powder, medicine powder, protein powder, etc. more

Hot sell shampoo lotion soap heating mixer machine This Heating Mixer Machine is suitable for cosmetics, chemical, pharmaceutical, food and other industries. Easy to operate and easy to use. more

All-in-one Automatic Liquid Filling Weighing And Cartoning Machine The Automatic Liquid Filling Sealing Machine is suitable for liquid, medicine, beverage, electronic cigarette oil, dairy product, health product, food, perfume, pesticide,cosmetics, fruit pulp, oil, etc. more

High Speed Oral Automatic Liquid Filling Sealing Machine APPLISCATION The Oral Liquid Filling Sealing Machine is suitable for unit metering of medicine, dairy product, health product,food, beverage, cosmetics, perfume, pesticide, fruit pulp etc. more

Full automatic pharmaceutical liquid filling and sealing machine This Oral Liquid Filling Machine is suitable for liquid, health products, food, perfume, medicine, beverage, pesticide, cosmetics, e-cigarette oil, dairy products, fruit pulp, oil and so on. more

Automatic Pharmaceutical Oral Liquid Filling and Sealing Machine The Liquid Filling and Sealing Machine is suitable for liquid, medicine, beverage, health product, food, perfume, pesticide,cosmetics, electronic cigarette oil, dairy product, fruit pulp, oil, etc. more

Stainless Steel Reverse Osmosis System can be widely used in the industrial area, such as medicine, electronics, electric power and surface cleaning and preparation of high-pressure boiler make-up water in thermal power plant.

Item NO.:

MZH-ROPayment:

L/C,D/A,D/P,T/T,Western UnionProduct Origin:

chinaShipping Port:

Huangpu,GaungzhouLead Time:

45 working daysReverse osmosis water filtration system reverse osmosis filter

Customized And OEM Service Available

DESCRIPTION

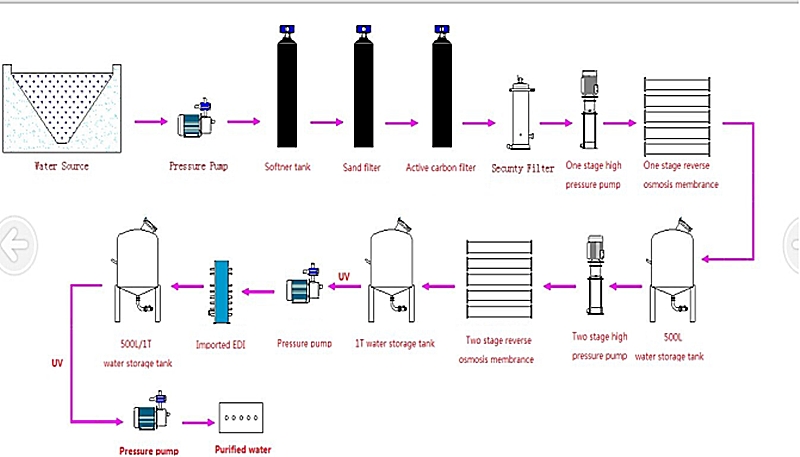

Ultra-pure Water System,Best Reverse Osmosis System through two times reverse osmosis system make the water quality reach standard of purified water. Ultra-pure water conductivity will less than 1 us, resistivity of 1.0-10x106,salinity<1mgk/L,stainless steel material,easy to operate..

STANDARD CONFIGURATION

Dow membrane

Nanfang high-pressure pump

Korean imported pressure switch

Imported electromagnetic valve, pressure Gage

(Two stage working progress)

EDI working principle

1. For pure water flow into the EDI system, the main part of the inflow of resin / membrane, and the other part along the lateral membrane and plate flow

2. Wash away with the ion which is outside of the membrane

3. The resin can interception the ion in the water

4. The ion which is being intercepted, under the electrode, the anion move towards the positive direction, the cation move towards the negative direction.

5. Cation through the cation membrane, discharge resin/film

6. Anion through the anion membrane, discharge resin/film

7. The concentrated ion will discharge from the waste water

8. Deionized water flows in from the resin / membrane

EDI advantage

1. The water quality has the best stability.

2. able to produce the ultra pure water which meet the user requirements continuously.

3. The modular production, and can realize the automatic control

4. No need acid-base regeneration, no sewage discharge

5. Will not need to shut down due to the regeneration

6. Don't need the regeneration equipment , storage and transport the chemicals.

7. The device has the advantages of compact structure and has small landing area.

8. Low operation cost and low repair cost

9. Simple operation, and low labor intensity

TECHNICAL SPECIFICATIONS

|

Model |

Productivity |

Power |

Recycle Rate(%) |

Purified WaterProductivity(us/cm) |

FeedWaterProductivity(us/cm) |

|

RO-0.25-S |

0.25T/H |

1.3kw |

50 |

3-8 |

≤300 |

|

RO-0.5-S |

0.5T/H |

1.3kw |

50 |

3-8 |

≤300 |

|

RO-1-S |

1T/H |

1.5kw |

65 |

3-8 |

≤300 |

|

RO-2-S |

2T/H |

2.0kw |

65 |

3-8 |

≤300 |

|

RO-3-S |

3T/H |

4.0kw |

75 |

3-8 |

≤300 |

|

RO-6-S |

6T/H |

5.5kw |

75 |

3-8 |

≤300 |

|

RO-10-S |

10T/H |

7.5kw |

75 |

3-8 |

≤300 |

|

RO-30-S |

30T/H |

11kw |

75 |

3-8 |

≤300 |

|

RO-60-S |

60T/H |

18.5kw |

75 |

3-8 |

≤300 |

Prev:

1000L/H Reverse Osmosis System industrial RO water treatment systemNext:

SUS Ro water treatment water treatment plantIf you have questions or suggestions,please leave us a message,we will reply you as soon as we can!